Business

CMO & CDMO

Contract Development and Manufacturing Organization

(Clinical trial) GMP Biomanufacturing

-

→ Recombinant DNA based cGMP Biomanufacturing Facility and Wide Work Experience

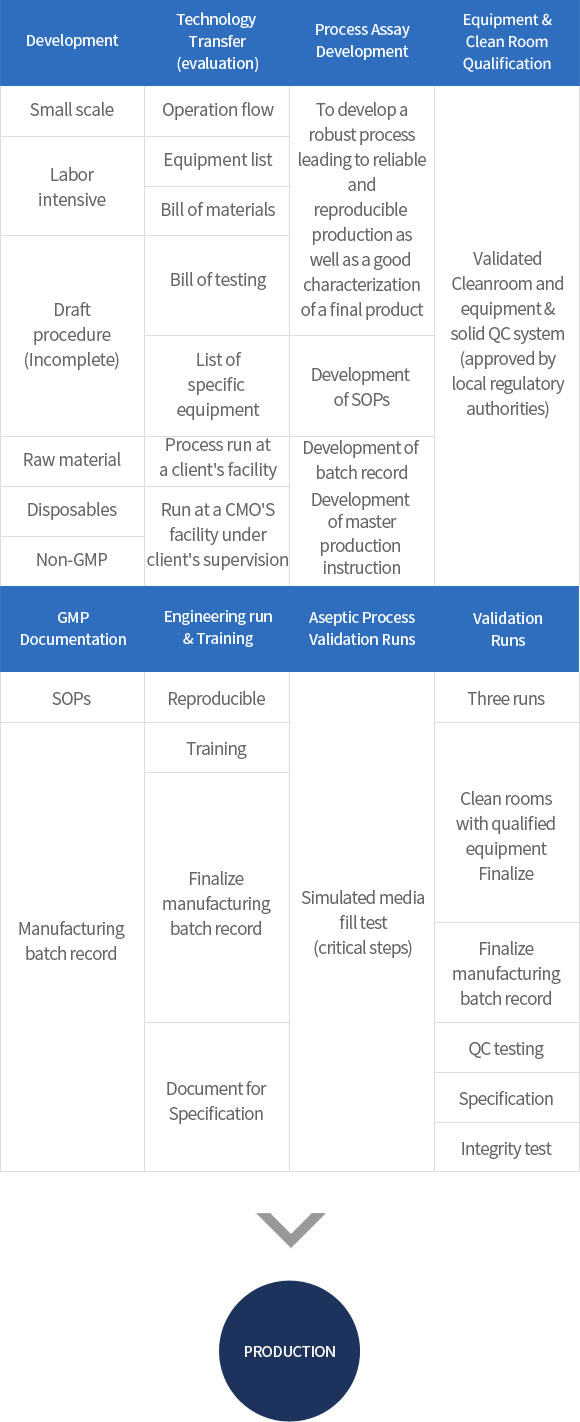

- ∙ cGMP Compliant Manufacturing Facility for (clinical trial) Biologics (Expected to be certified in 2020)

- ∙ Developing Reproducible Manufacturing Process from Small Scale to Commercial Scale

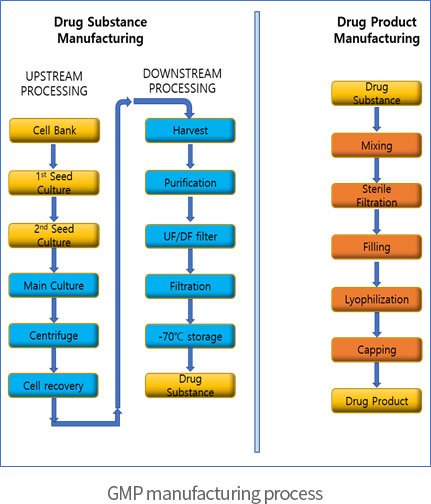

- ∙ cGMP Manufacturing and Process Technology for (clinical trial) Biologics based on Microbial Fermentation

- ∙ cGMP Manufacturing and Process Technology for Parenterals(Liquid, Freeze-dry)

- ∙ QA Experts Experienced with Various Inspections from Domestic and Overseas Regulatory Authority

- ∙ Quality Program (Quality system, Facilities & Equipment, Materials, Productions, Packaging & Labeling, Laboratory control) covers cGMP, EU-GMP, KGMP and ICH guidelines

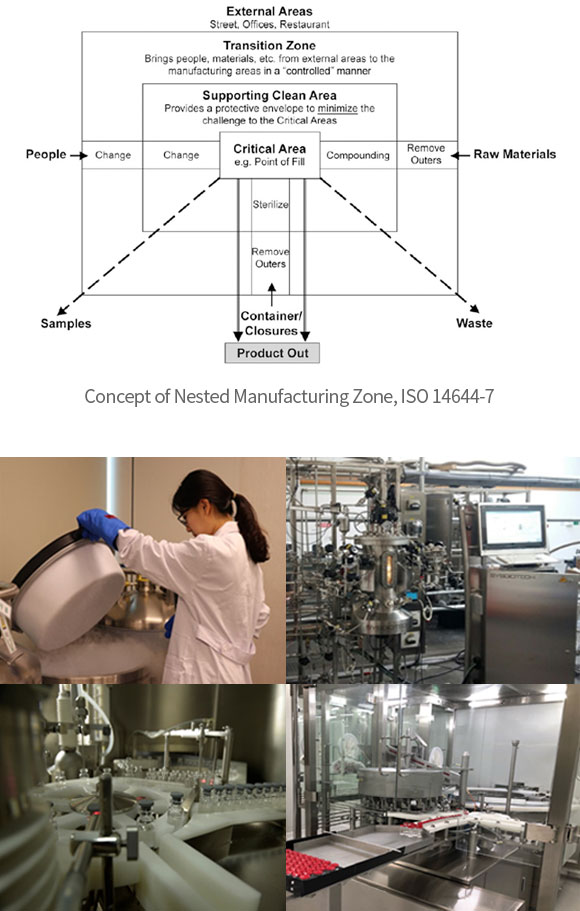

- ∙ Well Defined Manufacturing Environment: Grade A/B (Sterile filling and supporting area), Grade C/D (microbial control zone), CNC (Controlled not classified)

∙ Recombinant DDA based Biologics Develop Process

∙ GMP manufacturing and validation service for Drug Substance and Drug Product of (clinical trial) Biologics using recombinant DNA technology

Non-GMP manufacturing for non-clinical trial

-

→ To provide R&D and non-clinical trial drug production service from early stage development for DS and DP of microbial fermentation based recombinant biologics

- ∙ Fermentation and Purification Process for Recombination (E.coli) Cell Line

- ∙ Liquid Injection and Freeze-Drying Injection

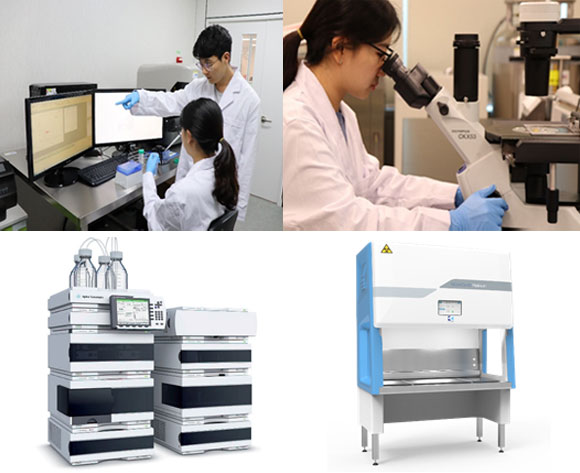

- ∙ Analytical Method Development (Identity, Quantity, Potency, Impurities)

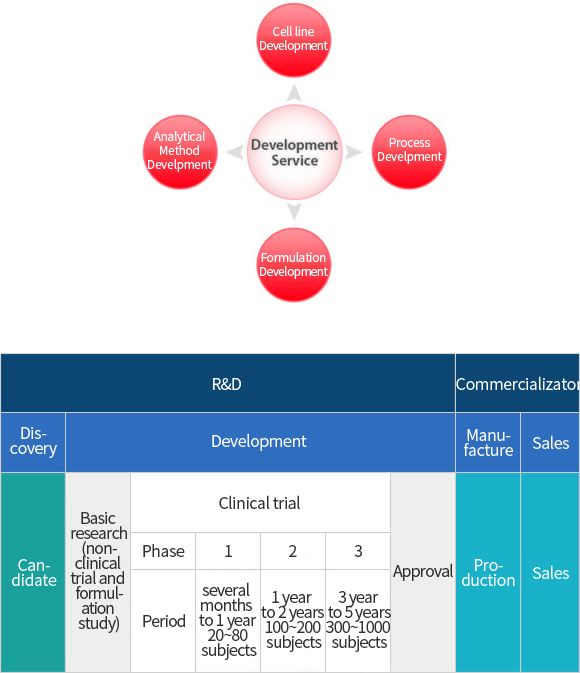

Customized Services

-

→ Customized Services including Manufacturing Process Development of biologics DS and DP

- ∙ Cell Line Screening for Recombinant DNA Biopharmaceuticals

- ∙ Development of Fermentation and Purification Condition Satisfied with Customer’s Requirements

- ∙ Optimization of Fermentation and Purification Process for Drug Substance

- ∙ Specialized to Validation and Regulatory Affairs Services

-

→ Fermentation process development

- ∙ Development and Improvement of Fermentation Condition

- ∙ Fermentation Process Development: Batch, Fed-batch, Seed Culture

- ∙ Basal Media and Feeding Media Screening

- ∙ Fermentation Process Optimization(Study regarding Process Parameters such as Feeding Strategy, Temperature, pH, Initial Cell Density, etc.)

- ∙ Setup for 50 L and 500 L Fermentation Process

-

→ Purification Process Development

- ∙ Process Improvement and Optimization

- ∙ Purification Process Development

- ∙ Type & Sizing test for UF/DF Membrane

- ∙ Setup for Purification Process

-

→ Scale-up Study

- ∙ 50 L/500 L Volume Process Setup and Analysis

- ∙ Technical Transfer of Manufacturing for (Non-) Clinical trial

-

→ Formulation Development

- ∙ Optimization on Product and Stability through Formulation Development for Protein and Excipients

- ∙ Formulation Development for Liquid Injection and Freeze-Drying Injection

-

→ Physico-chemical tests

- ∙ Identity, Quantity, Purity, Potency, Impurities, Endotoxin, Physico-chemical tests

- ∙ Specificity, Accuracy, Precision, Detection Limit, Quantitation, Limit, Linearity, Range, Robustness

- ∙ stability test

-

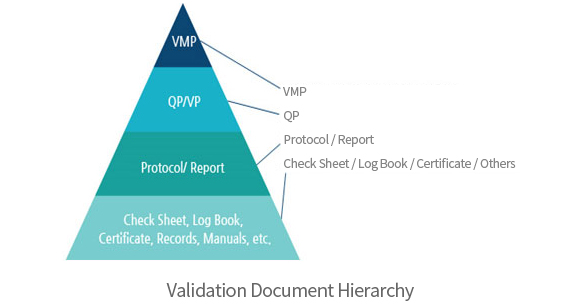

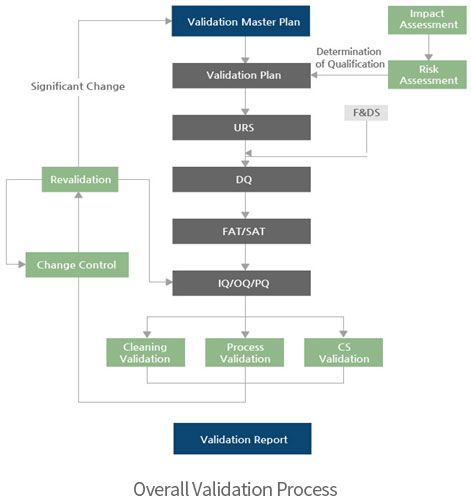

→ Validation

- ∙ Validation/Qualification

-

∙ Validation

- - Process Validation, PV

- - Cleaning Validation, CV

- - Computer System Validation, CSV

-

∙Qualification

- - System Impact Assessment, SIA

- - Risk Assessment, RA

- - User Requirements Specification, URS

- - Design Qualification, DQ

- - Factory Acceptance Test, FAT

- - Site Acceptance Test, SAT

- - Installation Qualification, IQ

- - Operational Qualification, OQ

- - Performance Qualification, PQ

-

Qualification

- - Qualification Planning

- - Process Equipment and Utilities

- - Water Generation and Distribution System):Purified Water, Water For Injection, Clean Steam

- - HVAC System

- - Compressed Air System

- - Clean Room

- - Computer and Automation System

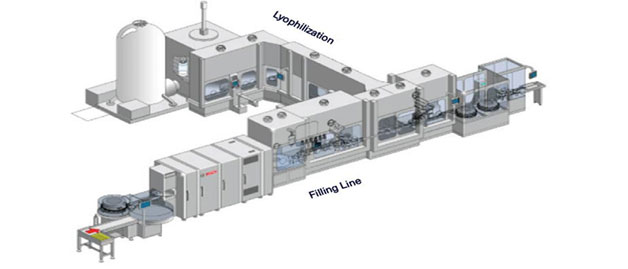

GMP plant (Osong district bio-plant)

-

→ Site Area

- ∙ 19,932 ㎡

-

→ Construction Schedule

- ∙ July of 2020 - completion expected

-

→ GMP Manufacturing Facility

- ∙ Raw and Packaging material storage (Including Sampling room, Weighing room)

- ∙ Drug product storage (Coldroom)

- ∙ Drug substance line (for microorganism fermentation & purification)

- ∙ Drug product line (for sterile injection & freeze-drying injection)

- ∙ Packing room (Auto inspection machine, Labelling machine, Packaging line)

- ∙ QC Lab (Weighing room, Physicochemical lab, Microbiogical lab, Stability/Retention sample room))

- ∙ Machine room (Pharmaceutical water generation/distribution system, HVAC system, Compressed air system)

-

→ Utilization Plan

- ∙ Non-clinical and Clinical Samples of new development items

- ∙ Commercial products manufacturing

- ∙ C(D)MO business

-

→ GMP Target

- ∙ Compliant with cGMP, EU EMA, KGMP and Other Global Agencies